Value Delivered

By utilizing 3D modeling capabilities and an extensive amount of pre-fabrication, Shambaugh was able to accelerate the project schedule, ensure quality control, and reduce overall project costs.

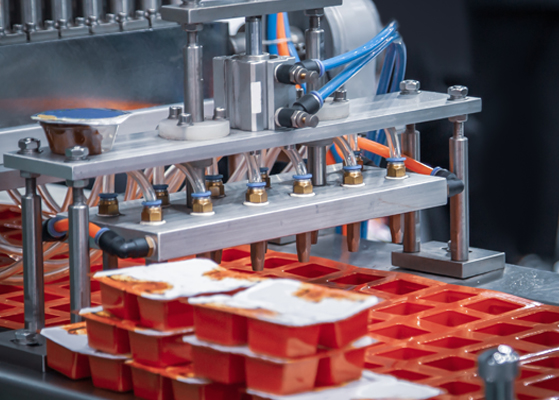

The food processing Design-Build project included tripling the ketchup capacity, and a fifty percent addition to salad dressing, jam, and jelly production.

The project was completed on budget and schedule. Shambaugh self-performed on a Design-Build basis: mechanical, electrical, food process, refrigeration, fire protection, and utilities services with its extensive team.

Client Objectives

The McCormick Company needed to expand and upgrade their existing 50,000 square foot salad dressing, jelly, jam, and condiment facility in South Bend, Indiana.

Solutions

- Designed in 3D modeling software to allow customer to tour and evaluate the installation prior to construction

- 3D CAD allowed engineer and customer to improve plant and system ergonomics while also increasing fabrication opportunities Totally automated bulk ingredient addition for maximum production capability

- Full week ketchup production without intermediate CIP

- 3 to 1 turndown rate on ketchup to match available packaging equipment

- CIP systems for fast effective cleaning to maximize production time

- Extensive use of product recovery systems to minimize valuable product loss while reducing high B.O.D. waste

- Integrated Process/CIP Plant Automation system

The key components to this project involved minimal disruption to the plant’s existing production and to upgrade automation and batch sequencing. The plant required diverse and efficient food processing to allow for quick change over related to multiple products.